Methyl methacrylate (MMA) is a key raw material used in the production of polymethyl methacrylate (PMMA), acrylic sheets, paints, coatings, adhesives, and various other applications. Its price is influenced by several factors, including raw material costs, production processes, market demand, and regulatory policies. This article provides a comprehensive analysis of the factors affecting Methyl Methacrylate Price Trend Analysis, historical trends, and future outlooks.

Key Factors Influencing Methyl Methacrylate Prices

Raw Material Costs

- Acetone: Acetone is a primary raw material in the production of MMA via the acetone cyanohydrin (ACH) process. Fluctuations in acetone prices can significantly impact the cost of MMA.

- Methanol: Methanol is another key raw material used in the production of MMA, especially in processes like the C4 direct oxidation method. Changes in methanol prices can influence MMA production costs.

- Isobutylene: Isobutylene is used in some MMA production processes, and its price can vary based on availability and market demand.

Production Processes

- Acetone Cyanohydrin (ACH) Process: The ACH process is the most common method for producing MMA. It involves the reaction of acetone and hydrogen cyanide, followed by hydrolysis and esterification. The cost of hydrogen cyanide and the efficiency of the process affect MMA prices.

- C4 Direct Oxidation Process: This process involves the oxidation of isobutylene to produce methacrolein and methacrylic acid, which are then esterified to produce MMA. The efficiency and cost of this process can impact MMA prices.

- Ethylene Process: This process uses ethylene as a feedstock to produce MMA. Although less common, it can influence market dynamics depending on regional feedstock availability and production costs.

Enquire For Regular Prices: https://www.procurementresource.com/resource-center/methyl-methacrylate-price-trends/pricerequest

Market Demand

- Acrylic Sheets and PMMA: The demand for MMA is closely tied to the production of PMMA and acrylic sheets, which are used in a variety of applications, including automotive, construction, and signage.

- Coatings and Adhesives: MMA is a key ingredient in various coatings, adhesives, and sealants. The demand from these sectors can significantly influence MMA prices.

- Geographic Variations: Demand for MMA varies globally, with higher demand in regions with robust industrial and construction activities.

Supply Dynamics

- Global Production Capacity: The global production capacity of MMA, including the number of manufacturing plants and their production efficiencies, influences supply levels and prices. Changes in production capacity due to plant closures or new facilities can impact market supply.

- Trade Policies: International trade policies, including tariffs and trade agreements, can affect the global supply chain of MMA. Changes in trade policies in major producing or consuming countries can impact prices.

Environmental Regulations

- Emissions and Waste Management: The production of MMA involves handling hazardous chemicals and emissions. Stringent environmental regulations can increase production costs due to the need for emissions control, waste management, and compliance with safety standards.

- Sustainability Initiatives: Increasing demand for environmentally friendly and sustainable products can influence the production processes and costs of MMA. Companies may need to invest in greener technologies and practices to meet regulatory and consumer expectations.

Historical Price Trends

Price Volatility

MMA prices have historically shown significant volatility due to fluctuations in raw material costs, energy prices, and market demand. For example, periods of high demand in the automotive and construction sectors can lead to price spikes, while economic downturns can result in decreased demand and lower prices.

Technological Advancements

Advancements in production technologies and processes have helped improve the efficiency and cost-effectiveness of MMA manufacturing. Innovations in chemical synthesis and recycling methods have contributed to more stable prices by reducing dependence on raw materials and energy.

Environmental Compliance

Increasingly stringent environmental regulations have led to higher production costs for MMA. However, these regulations have also driven innovation in cleaner and more efficient production techniques, helping to mitigate some of the cost impacts over time.

Case Studies of Major Methyl Methacrylate Markets

United States

The United States is a significant producer and consumer of MMA, particularly in the automotive and construction sectors. Key factors influencing MMA prices in the U.S. include:

- Market Demand: Demand from the automotive, construction, and electronics sectors drives the market for MMA.

- Environmental Regulations: Stringent environmental regulations aimed at reducing emissions and promoting sustainability have increased production costs but also promoted the adoption of cleaner technologies.

- Trade Policies: Changes in trade policies, such as tariffs on imported raw materials and finished products, can affect the cost and availability of MMA.

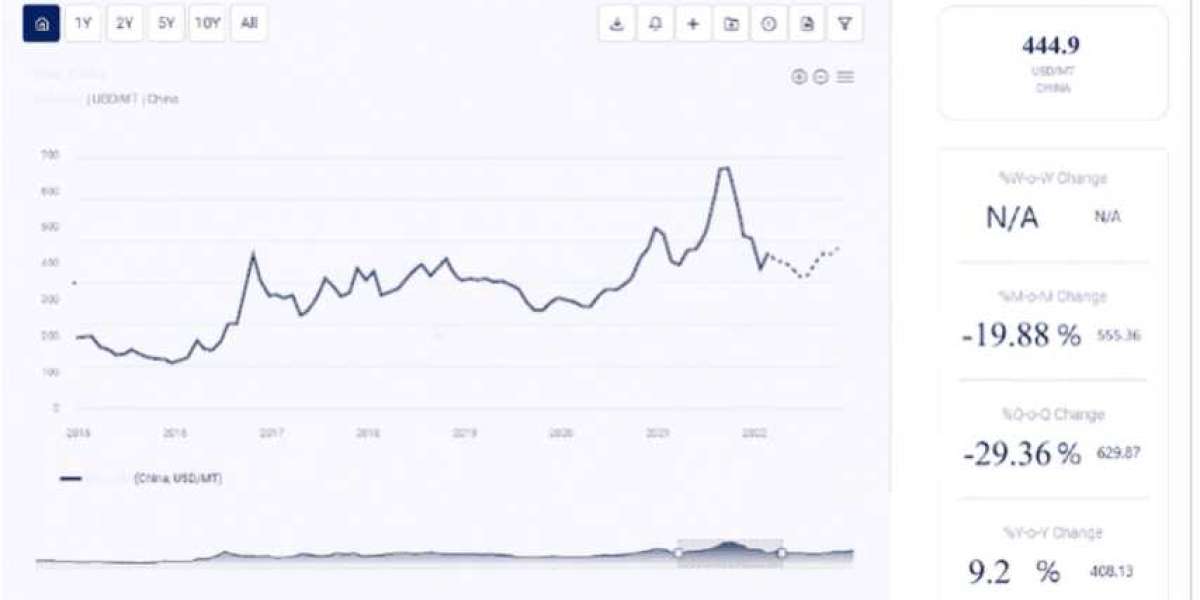

China

China is one of the largest producers and consumers of MMA. The country’s demand is driven by its vast industrial and construction sectors. Key factors influencing MMA prices in China include:

- Industrial Growth: Rapid industrialization and urbanization have driven demand for MMA in various applications, impacting prices.

- Environmental Regulations: Stricter environmental policies aimed at reducing emissions and improving sustainability have increased production costs but also promoted the adoption of cleaner technologies.

- Supply Chain Dynamics: China’s significant production capacity and export-oriented industry influence global supply and prices.

The Impact of Climate Change on Methyl Methacrylate Production Costs

Climate change poses several challenges to MMA production, particularly regarding resource availability and regulatory pressures to reduce carbon emissions. Key impacts include:

- Resource Availability: Changes in climate conditions can affect the availability of raw materials such as acetone and methanol. Extreme weather events, such as floods and droughts, can disrupt production and supply chains, leading to price volatility.

- Carbon Pricing: Implementing carbon pricing mechanisms, such as carbon taxes or cap-and-trade systems, can increase the cost of energy and raw materials, making MMA production more expensive. This incentivizes the adoption of cleaner technologies and alternative energy sources.

- Sustainability Initiatives: The chemical industry is increasingly focusing on sustainability initiatives, such as reducing carbon emissions and promoting responsible sourcing of raw materials. These initiatives can influence production costs and market dynamics.

Future Prospects of Methyl Methacrylate

Technological Innovations

- Advanced Production Technologies: Continued innovation in production technologies, such as more efficient chemical synthesis methods and the use of renewable energy sources, will play a significant role in reducing production costs and environmental impact.

- Sustainable Practices: Implementing sustainable practices, such as recycling and waste reduction, will be crucial for the long-term viability of the MMA industry.

Market Dynamics

- Growing Demand: The demand for MMA is expected to grow, driven by increasing industrialization, urbanization, and the expansion of end-use industries such as automotive, construction, and electronics.

- Global Trade: The dynamics of global trade will continue to influence the MMA market. Ensuring competitive pricing and quality will be essential for maintaining market share in the face of international competition.

Policy and Regulatory Support

- Government Initiatives: Supportive government policies and initiatives aimed at promoting sustainable chemical production and reducing carbon emissions will be crucial for the future of the MMA industry.

- International Cooperation: Collaboration between countries on climate goals and industrial standards will help harmonize regulations and promote best practices in MMA production.

Conclusion

Methyl methacrylate (MMA) remains a vital chemical compound in numerous industries due to its effectiveness in various applications, including automotive, construction, and electronics. The industry faces significant challenges, including economic pressures, environmental concerns, and technological demands. However, advancements in technology, supportive policies, and evolving market dynamics present opportunities for growth and innovation. As the world moves towards more sustainable and efficient production methods, the MMA industry must adapt to maintain its relevance and contribute to a cleaner, more resilient global economy. By addressing its challenges and leveraging its strengths, the MMA sector can continue to thrive and support the development of various industries worldwide.