As 3D printing technology continues to evolve, it has become increasingly important to address the potential health risks associated with evaluating the safety of 3D printer emissions. This guide aims to provide a thorough understanding of the emissions produced during the 3D printing process and how to assess their safety.

What Are 3D Printer Emissions?

3D printers, particularly those using thermoplastics, can emit various volatile organic compounds (VOCs) and ultrafine particles (UFPs). These emissions can vary based on the type of material used, the printer's operating conditions, and the environment in which the printing occurs. Understanding these emissions is crucial for evaluating their potential impact on health and safety.

Key Emission Types

- Volatile Organic Compounds (VOCs): These are chemicals that can evaporate into the air and may cause respiratory issues or other health problems.

- Ultrafine Particles (UFPs): These tiny particles can penetrate deep into the lungs and enter the bloodstream, posing serious health risks.

- Odors: While not always harmful, unpleasant odors can indicate the presence of harmful emissions.

Evaluating the Safety of 3D Printer Emissions

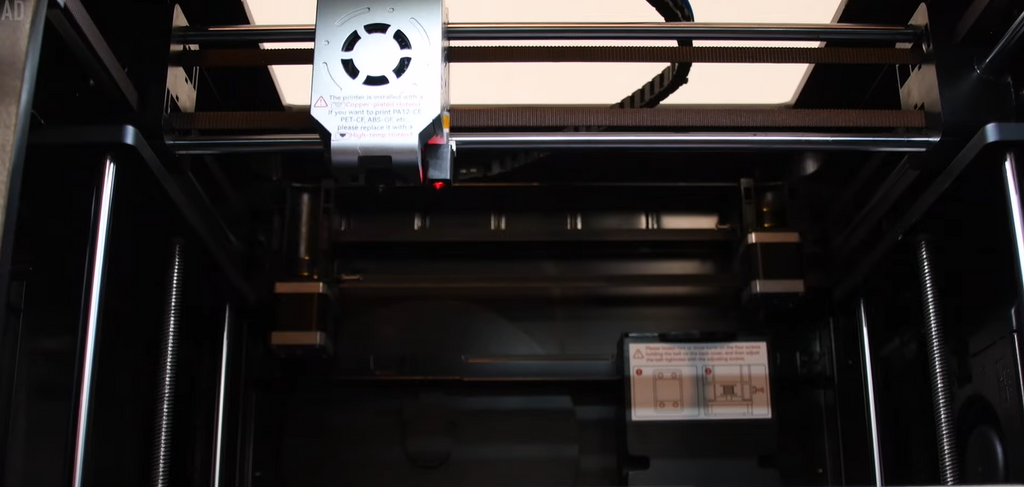

When assessing the safety of 3D printer emissions, several factors must be considered. What materials are being used? How is the printer maintained? Are there adequate ventilation systems in place? Each of these elements plays a significant role in determining the overall safety of the printing environment.

Factors to Consider

- Material Selection: Different materials emit varying levels of VOCs and UFPs. For instance, PLA is generally considered safer than ABS.

- Printer Settings: Higher temperatures can lead to increased emissions. Adjusting settings can mitigate risks.

- Ventilation: Ensuring proper airflow can significantly reduce the concentration of harmful emissions in the workspace.

Mitigation Strategies for Safe 3D Printing

To ensure a safe printing environment, it is essential to implement effective mitigation strategies. These strategies can help in evaluating the safety of 3D printer emissions and minimizing health risks.

Recommended Practices

- Use Enclosed Printers: Enclosures can help contain emissions and improve air quality.

- Install Filtration Systems: HEPA filters can capture UFPs, while activated carbon filters can reduce VOCs.

- Regular Maintenance: Keeping printers clean and well-maintained can prevent excessive emissions.

Conclusion

In conclusion, understanding and evaluating the safety of 3D printer emissions is vital for anyone involved in 3D printing. By being aware of the types of emissions produced, considering various factors, and implementing effective mitigation strategies, users can create a safer printing environment. As technology advances, ongoing research will be essential to ensure that 3D printing remains a safe and beneficial tool for innovation.