When it comes to reinforcing concrete structures, Sail TMT Bars are a top choice for construction professionals. As leading Sail TMT Bars suppliers in Maharashtra, we understand the critical role these materials play in ensuring the strength and durability of your projects.

Understanding Sail TMT Bars

What Are Sail TMT Bars?

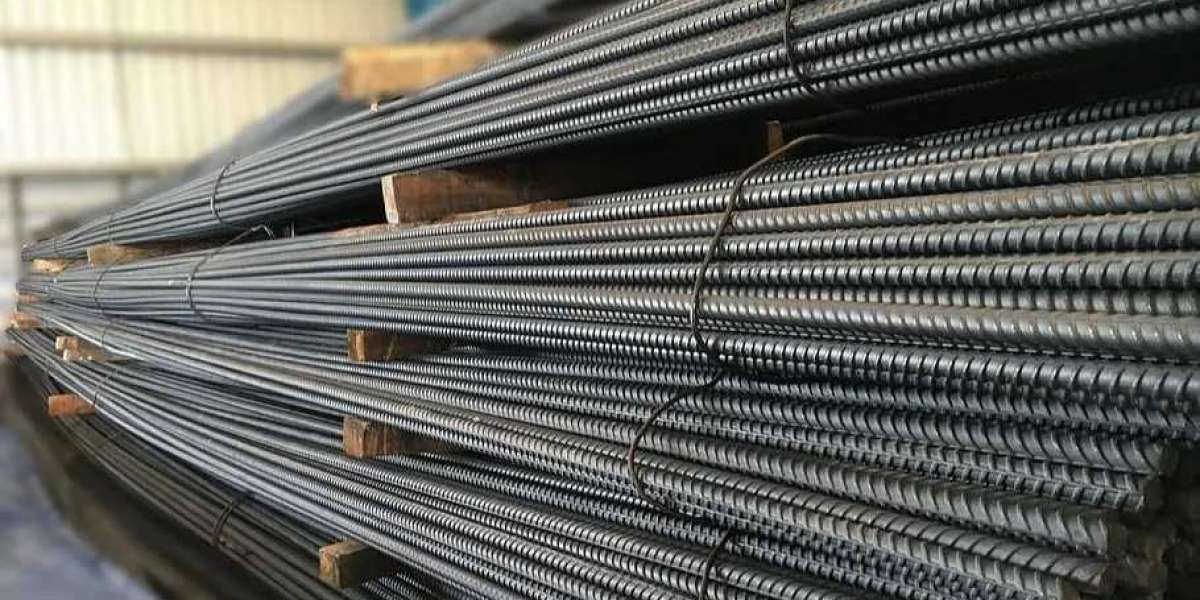

Sail TMT Bars are a type of thermomechanically treated steel bars manufactured by Steel Authority of India Limited (SAIL). These bars undergo a rigorous heat treatment process, which enhances their mechanical properties, making them suitable for various construction applications. The treatment process involves quenching the bars in water and then allowing them to cool gradually, resulting in a tough outer layer and a softer core that provides superior tensile strength and ductility.

Why Sail TMT Bars Are Essential

Sail TMT Bars offer several advantages over conventional steel bars. Their enhanced strength, flexibility, and corrosion resistance make them ideal for a wide range of construction projects, from residential buildings to large-scale infrastructure. By choosing Sail TMT Bars, you ensure that your construction projects are reinforced with high-quality materials that meet stringent industry standards.

Key Factors to Consider When Choosing Sail TMT Bars

ISI Certification and Quality Assurance

One of the most critical factors to consider when selecting Sail TMT Bars is their ISI certification. The Indian Standards Institute (ISI) certification ensures that the bars meet high-quality standards and have undergone rigorous testing for various parameters, including chemical composition, mechanical properties, and physical characteristics. As leading Sail TMT Bars suppliers in Maharashtra, we prioritize providing ISI-certified products to guarantee the quality and reliability of the materials you use.

Grade of Sail TMT Bars

Sail TMT Bars come in various grades, each designed for specific construction requirements:

- Fe-415: This grade is suitable for small-scale residential projects and provides good strength and flexibility for moderate load-bearing applications.

- Fe-500: Commonly used in high-rise buildings, bridges, and industrial structures, Fe-500 grade bars offer a balanced combination of strength and flexibility.

- Fe-550: Ideal for heavy-duty applications, Fe-550 grade bars are used in projects requiring higher strength, such as large industrial buildings and infrastructure.

- Fe-600: This grade is designed for extreme load-bearing capacity and is used in specialized projects like dams and power plants.

Selecting the appropriate grade of Sail TMT Bars based on your project's specific needs is crucial for ensuring structural integrity and cost-effectiveness.

Strength and Flexibility

The strength of Sail TMT Bars is measured by their yield strength and ultimate tensile strength. Yield strength represents the maximum stress a bar can endure without permanent deformation, while ultimate tensile strength indicates the maximum stress before breaking. Flexibility, or ductility, is also essential as it allows the bars to bend without breaking, which is particularly important in seismic-prone areas.

Corrosion Resistance

Corrosion resistance is a vital factor in ensuring the longevity of TMT bars, especially in coastal areas or regions with high humidity. Sail TMT Bars are designed with superior corrosion resistance properties, making them suitable for harsh environmental conditions. Look for bars with anti-corrosion treatments or coatings to enhance their durability.

Bonding Strength with Concrete

The rib pattern on Sail TMT Bars plays a significant role in bonding strength with concrete. Properly designed ribs increase the surface area for a strong bond, which is crucial for the structural performance of reinforced concrete. Ensure that the bars you choose have well-defined and uniform rib patterns for optimal bonding.

Advantages of Choosing Sail TMT Bars

Quality Assurance and Safety

Sail TMT Bars are known for their high quality and consistency. As one of the top Sail TMT Bars suppliers in Meghalaya, we emphasize the importance of using high-quality materials to ensure safety and performance. ISI certification and adherence to strict manufacturing standards provide peace of mind that the bars will perform reliably over time.

Cost-Effectiveness

While Sail TMT Bars may come with a higher initial cost compared to non-branded or lower-quality options, they offer significant long-term benefits. Their superior strength, durability, and corrosion resistance reduce the need for frequent repairs and maintenance, ultimately leading to cost savings over the lifespan of the structure.

Comparing Sail TMT Bars with Other Brands

Sail vs. Non-Brand TMT Bars

Sail TMT Bars are manufactured by Steel Authority of India Limited, a reputable and well-established brand in the industry. Compared to non-branded TMT bars, Sail TMT Bars offer better quality assurance, consistent performance, and adherence to industry standards. Non-branded bars may vary in quality and reliability, potentially leading to higher risks of structural issues.

Sail vs. Competitor Brands

When comparing Sail TMT Bars with other leading brands, consider factors such as strength, flexibility, corrosion resistance, and cost. Sail TMT Bars are known for their superior performance and adherence to quality standards, making them a preferred choice for many construction professionals.

Common Myths About Sail TMT Bars

Myth 1: All TMT Bars Are the Same

Not all TMT bars are created equal. The quality, strength, and performance of TMT bars can vary significantly based on the manufacturing process and the brand. Sail TMT Bars are known for their high quality and consistency, making them a reliable choice for construction projects.

Myth 2: Higher Grade Bars Are Always Better

While higher-grade Sail TMT Bars offer greater strength, they are not always the best choice for every project. The grade of TMT bars should be selected based on the specific requirements of the construction project. Using a higher grade than necessary can increase costs without providing additional benefits.

Myth 3: TMT Bars Don't Require Maintenance

Although Sail TMT Bars are designed to be durable and low-maintenance, they still require regular inspections and proper maintenance. Ensuring that the bars are not exposed to conditions that could lead to corrosion or damage is essential for maintaining the structural integrity of the reinforced concrete.

Tips for Purchasing Sail TMT Bars

Choose Reputable Suppliers

Selecting a reputable supplier is crucial to ensure you receive high-quality Sail TMT Bars. Look for suppliers with a proven track record and positive customer reviews. As leading Sail TMT Bars suppliers in Maharashtra, we are committed to delivering top-quality products and excellent customer service.

Verify ISI Certification

Always verify the ISI certification of Sail TMT Bars before purchasing. This certification ensures that the bars meet the required quality standards and have undergone rigorous testing.

Inspect the Bars

Before making a purchase, inspect the Sail TMT Bars for any visible defects, such as cracks, rust, or uneven surfaces. Ensure that the bars have uniform rib patterns and are free from damage.

Consider Delivery and Storage

Proper delivery and storage of Sail TMT Bars are essential to maintain their quality. Ensure that the bars are transported and stored in a manner that prevents damage and corrosion. Store the bars in a dry and covered area to protect them from moisture and environmental factors.

Conclusion

Choosing the right Sail TMT Bars for your construction project is a crucial decision that impacts the safety, durability, and cost-effectiveness of the structure. By considering factors such as ISI certification, grade, strength, flexibility, corrosion resistance, and bonding strength, you can make an informed choice that meets the specific requirements of your project. As one of the leading Sail TMT Bars suppliers in Meghalaya, we are dedicated to providing high-quality materials that ensure the success and longevity of your construction endeavors.

Investing in Sail TMT Bars means investing in the safety and durability of your construction projects. Make the right choice and build with confidence, knowing that your structures are reinforced with some of the best materials available.